The practical training provided valuable exposure to industry practices and enhanced my technical and professional skills.

A Permit to Work System is a formal safety procedure used to control high-risk activities on site. It ensures that hazards are identified in advance and all necessary safety measures are implemented before work begins. Authorized personnel review and approve each permit to verify safe working conditions. This system strengthens communication between teams and clearly defines responsibilities. It helps prevent accidents and maintains full compliance with safety standards.

Work Method Statements outline the safe and approved steps required to perform a specific task. They include details such as equipment, manpower, potential hazards, and control measures. These statements guide workers to complete tasks efficiently while following established safety practices. They also support supervisors in maintaining consistent safety performance across all activities. Method statements reduce risks and promote a standardized approach to workplace safety.

An HSE Policy reflects an organization’s commitment to protecting the health, safety, and environment of all stakeholders. It defines the company’s safety goals, responsibilities, and expectations for employees at every level. The policy ensures compliance with legal regulations and supports continuous improvement in workplace safety. It plays a vital role in developing a proactive safety culture. A strong HSE Policy promotes accountability and safer working environments.

An EHS Plan provides a structured approach to managing safety throughout the duration of a project. It includes hazard assessments, emergency procedures, training requirements, PPE guidelines, and defined responsibilities. The plan ensures that all project activities are carried out in a controlled and risk-free environment. It aligns contractors and clients on safety expectations and implementation strategies. A well-developed EHS Plan is essential for effective safety management and regulatory compliance.

An Observation Report documents unsafe acts, unsafe conditions, or positive safety behaviors identified during routine site checks. It enables early detection of potential hazards before they result in incidents. These reports encourage workers to participate in maintaining a safe workplace. Regular observations help improve risk control measures and overall safety performance. This proactive approach supports continuous improvement across all operations.

Incident Investigation Reports are prepared to determine the root causes of accidents, near misses, and other safety events. They involve collecting evidence, interviewing witnesses, and analyzing underlying factors. The goal is to recommend corrective and preventive actions that reduce the likelihood of future incidents. These reports are important for legal compliance, accountability, and improving safety systems. Effective investigations promote learning and strengthen organizational safety culture.

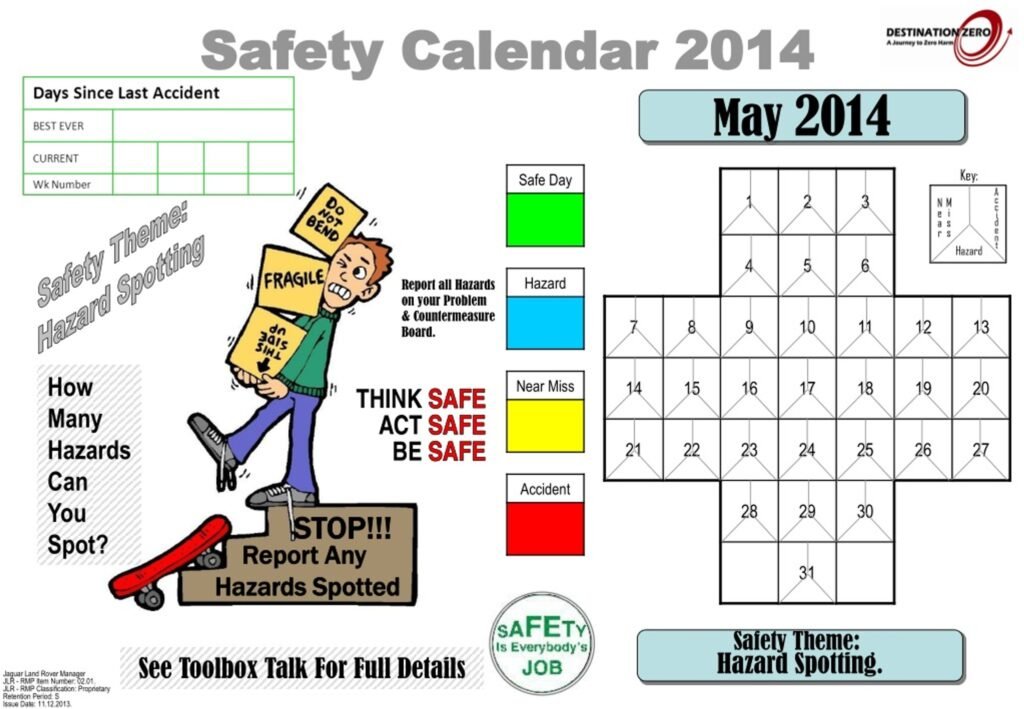

A Safety Calendar outlines scheduled safety activities such as trainings, inspections, meetings, and awareness programs. It keeps all teams informed about upcoming safety events and helps maintain consistent planning. Using a structured calendar ensures that important safety tasks are never overlooked. It supports compliance with safety requirements and strengthens organizational discipline. A well-planned Safety Calendar enhances engagement and builds a proactive safety environment.

A Safety Checklist is a practical tool used to conduct thorough inspections of the worksite. It highlights essential safety points that must be verified to ensure safe working conditions. Checklists help identify hazards quickly and support timely corrective actions. They promote consistency in daily, weekly, or monthly safety inspections. Using checklists improves overall safety compliance and reduces the risk of incidents.

A Safety Checklist is a practical tool used to conduct thorough inspections of the worksite. It highlights essential safety points that must be verified to ensure safe working conditions. Checklists help identify hazards quickly and support timely corrective actions. They promote consistency in daily, weekly, or monthly safety inspections. Using checklists improves overall safety compliance and reduces the risk of incidents.