Bunding in Safety: In safety and environmental management, some controls look simple but save millions in losses. Bunding is one of those controls.

It is not complex, not expensive, yet it plays a critical role in preventing disasters.

This article explains what bunding is, why it is important, where it is used, and how it controls major losses, with practical examples.

What Is Bunding in Safety?

Bundingin Safety is a secondary containment system.

It is usually a raised barrier, wall, or enclosure built around tanks, drums, or storage areas that contain liquids.

The main purpose of bunding is very simple:

To stop hazardous liquids from spreading if a leak, spill, or tank failure occurs.

In safety terms, bunding is a last line of defense when the primary container fails.

Why Is Bunding in Safety an Important Safety Term?

Bunding is interesting because it works silently.

Most of the time, no one notices it—until something goes wrong.

When spills happen:

- Fires are prevented

- Environmental damage is reduced

- Cleanup costs are controlled

- Legal penalties are avoided

Many major industrial accidents became disasters only because bunding was missing or poorly designed.

Where Is Bunding Mainly Used?

Bunding is widely used in industries where liquids pose a risk.

Common Areas Where Bunding Is Required

- Oil and fuel storage tanks

- Chemical warehouses

- Diesel generators and fuel stations

- Transformer oil areas

- Paint, solvent, and acid storage rooms

- Pharmaceutical and manufacturing plants

Environmental regulators and safety authorities strongly recommend bunding in these locations.

Bunding in Safety: How Bunding Controls Major Losses

Bunding works on a loss-prevention principle.

Without Bunding

- Liquid spreads quickly

- Fire risk increases

- Soil and groundwater get contaminated

- Production stops

- Heavy fines and legal action follow

With Bunding

- Spill remains confined

- Fire load is controlled

- Environment is protected

- Cleanup is faster and cheaper

- Business continuity is maintained

This is why bunding is considered a major loss control barrier in safety management systems.

Bunding in Safety: Real-Life Example of Bunding Effectiveness

Imagine a diesel storage tank develops a crack at night.

- Without bunding:

Diesel spreads across the site, enters drains, and creates fire and pollution hazards. - With bunding:

Diesel stays inside the bund wall.

The spill is contained, reported, cleaned, and operations resume safely.

Same incident. Very different outcome.

Common Bunding in Safety Techniques

Different situations require different bunding solutions.

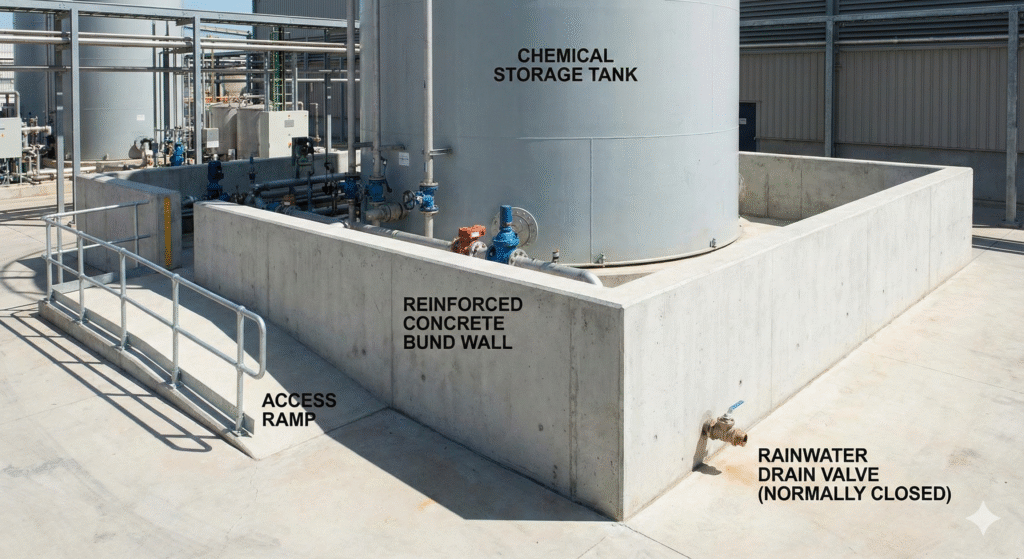

1. Concrete Bund Walls

- Permanent and strong

- Used for large tanks and fixed installations

2. Steel Bunds

- Used in industrial plants

- Durable and space-efficient

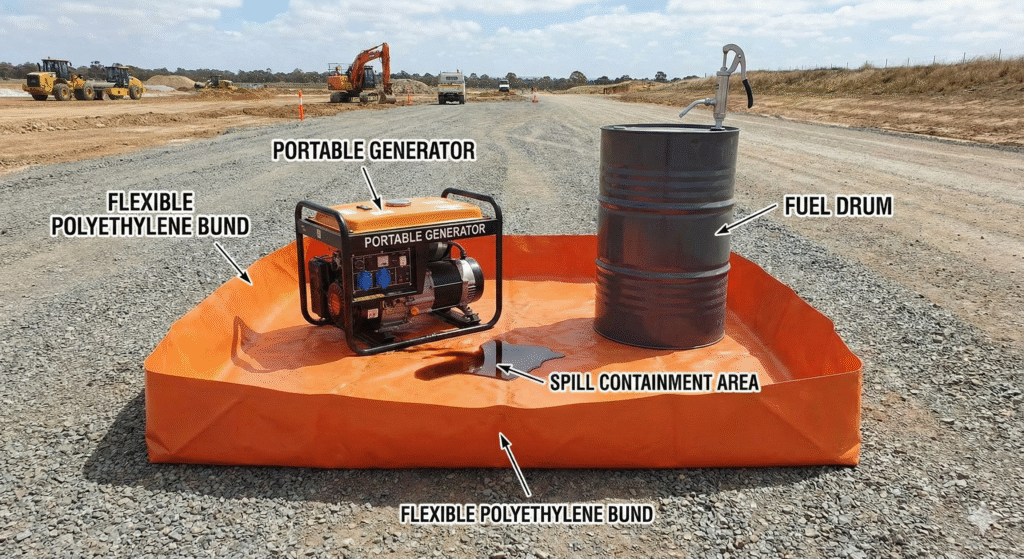

3. Portable Bunds

- Used for drums and temporary storage

- Flexible and cost-effective

4. Earth Bunds

- Used in oil fields and outdoor tank farms

- Must be properly compacted and lined

Basic Bunding Design Rule (Easy to Remember)

A common safety rule is:

Bunding capacity should be at least 110% of the largest container stored.

This ensures that even if the largest tank fails completely, the spill remains contained.

Bunding and Environmental Responsibility

Bunding is not only about safety—it is about environmental protection.

Regulatory bodies like Occupational Safety and Health Administration, Environmental Protection Agency, and Health and Safety Executive emphasize secondary containment to prevent pollution and long-term environmental damage.

Companies that ignore bunding often face:

- Regulatory penalties

- Reputation damage

- Loss of public trust

Key Lessons from Bunding

- Accidents are not always preventable, but losses are

- Simple controls can stop major disasters

- Bunding protects people, property, and the environment

- Prevention is always cheaper than recovery