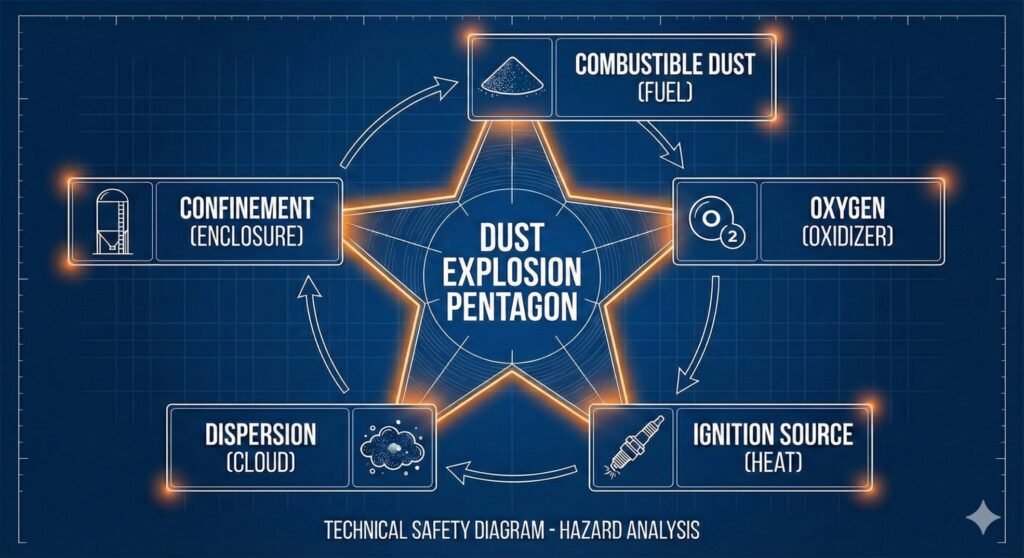

The Dust Pentagon is a recognized safety model used in process safety and fire protection engineering to explain the conditions required for a combustible dust explosion. It expands upon the traditional fire triangle by identifying two additional elements—dispersion and confinement—which are critical in transforming a dust fire into a violent explosion.

This model is widely applied in hazard identification (HAZID), risk assessments, HAZOP studies, and accident investigations across industries that handle combustible particulate solids.

Origin and Development of the Dust Pentagon

The dust pentagon evolved from early fire science research following several catastrophic industrial dust explosions. These incidents demonstrated that fuel, oxygen, and ignition alone were insufficient to explain explosion severity.

Investigations revealed that:

- Suspended dust clouds dramatically increase combustion speed

- Enclosed or semi-enclosed spaces allow pressure to build rapidly

As a result, safety engineers introduced the five-element dust pentagon model to systematically analyze explosion risks in mills, silos, conveyors, ducting, and enclosed workspaces.

Elements of the Dust Pentagon (Step-by-Step)

A dust explosion can occur only when all five elements are present simultaneously.

1. Combustible Dust (Fuel)

Combustible dust consists of finely divided solid particles capable of rapid oxidation when ignited. Explosibility depends on:

- Particle size

- Moisture content

- Chemical composition

Examples include:

- Organic dusts: flour, sugar, starch, wood

- Metal dusts: aluminium, magnesium, titanium

2. Oxidant (Oxygen)

Atmospheric oxygen acts as the oxidizing agent. Since oxygen is readily available in most workplaces, controlling oxygen is rarely practical. Therefore, fuel and ignition control become the primary prevention strategies.

3. Ignition Source

Ignition energy may arise from:

- Mechanical friction

- Electrostatic discharge

- Hot surfaces

- Open flames

- Electrical faults

Many combustible dusts have very low Minimum Ignition Energy (MIE), meaning even weak sparks can trigger ignition.

4. Dispersion (Dust Cloud Formation)

Dust must be suspended in air at a concentration within its explosive range.

Common dispersion activities include:

- Material transfer and pouring

- Pneumatic conveying

- Vibration and impact

- Poor housekeeping disturbing settled dust

Without dispersion, a dust explosion cannot occur.

5. Confinement

Confinement allows pressure to rise rapidly during combustion.

This may occur in:

- Process equipment (silos, cyclones, ducting)

- Conveyors and enclosed machinery

- Partially enclosed rooms or buildings

Without confinement, ignition may result in a flash fire rather than an explosion.

Industries Where the Dust Pentagon Is Commonly Found

The dust pentagon is relevant wherever combustible particulate solids are produced, processed, or stored, including:

- Food and grain processing (flour mills, sugar plants)

- Woodworking and furniture manufacturing

- Pharmaceutical and chemical powder handling

- Metal processing and additive manufacturing

- Coal handling and power generation

- Cement, plastics, and rubber industries

These environments often unknowingly contain all five elements, creating significant explosion potential.

Control Measures Based on the Dust Pentagon

Effective prevention requires eliminating or controlling at least one element of the pentagon. Controls are typically layered using engineering and administrative measures.

Fuel and Dispersion Control

- Dust minimization through enclosed systems

- High-efficiency local exhaust ventilation (LEV)

- Strict housekeeping programs

- Use of wet methods where feasible

Ignition Control

- Hot work permit systems

- Static electricity bonding and earthing

- Temperature monitoring of bearings and machinery

- Explosion-protected electrical equipment

Confinement and Explosion Protection

- Explosion venting and relief panels

- Explosion suppression systems

- Isolation valves to prevent flame propagation

- Equipment designed to withstand explosion pressure

Effectiveness of the Dust Pentagon in Industry

The dust pentagon is highly effective as both a technical analysis tool and a risk communication model. It helps HSE professionals, engineers, and operators understand:

- Why dust explosions occur

- Where hidden risks exist

- Which control measures are most effective

By mapping processes against the five elements, organizations can:

- Identify latent explosion hazards

- Prioritize engineering controls

- Improve compliance with process safety requirements

- Reduce catastrophic loss potential

The model is widely used in HAZOPs, safety audits, toolbox talks, and incident investigations.

Conclusion

The dust pentagon provides a structured and scientifically grounded framework for understanding and preventing combustible dust explosions. By recognizing the interaction between combustible dust, oxygen, ignition, dispersion, and confinement, safety professionals can implement targeted controls and significantly reduce the likelihood of catastrophic industrial incidents.