Isolation in safety is the process of separating workers from hazardous energy sources by physically disconnecting, blocking, locking, or neutralizing those sources before any work begins. Its purpose is to ensure no energy—electrical, mechanical, hydraulic, pneumatic, thermal, or chemical—can be released unexpectedly during maintenance, inspection, installation, or modification tasks.

Isolation is particularly critical in MEP systems and industrial plants, where multiple energy sources exist within one system. Failure to isolate hazards is a major contributor to fatal workplace incidents.

Why Isolation Is Crucial

Isolation is a life-critical safety control. Many serious accidents occur when equipment is assumed safe but remains energized or pressurized. Proper isolation:

- Prevents unexpected startup of machinery

- Protects workers from electrical shock, burns, crushing, or pressure release

- Controls stored and residual energy

- Ensures safe maintenance in MEP and industrial systems

- Complies with international safety regulations

Golden Rule: No isolation, no verification, no work.

Types of Isolation

1. Electrical Isolation

Ensures no live electrical energy reaches equipment:

- Switch off main isolators, MCC feeders, or DBs

- Lock circuit breakers, remove fuses

- Test voltage to confirm zero energy

Applications: HVAC panels, motors, pumps, chillers, elevators, plant machinery

2. Mechanical Isolation

Prevents movement or stored mechanical energy:

- Block rotating parts, disconnect belts or couplings

- Install mechanical stops or pins

Applications: Fans, AHUs, conveyors, compressors, turbines, presses

3. Process / Plant Isolation

Controls flow of fluids, gases, steam, or materials:

- Close and lock valves

- Blanking or blinding pipelines

- Double block and bleed

Applications: Boilers, refineries, chemical plants, steam/fuel lines

4. Hydraulic Isolation

Prevents movement from pressurized oil systems:

- Isolate hydraulic pumps

- Lock control valves

- Release residual pressure

Applications: Lifts, presses, heavy plant equipment

5. Pneumatic Isolation

Controls compressed air energy:

- Close supply valves, drain lines

- Lock pneumatic systems

Applications: HVAC dampers, air tools, automated equipment

6. Chemical Isolation

Protects against toxic, flammable, or corrosive substances:

- Drain chemical lines, purge with inert gas

- Physically disconnect sources

Applications: Treatment plants, industrial cleaning, process industries

7. Thermal Isolation

Controls heat and cold energy:

- Isolate steam lines, chillers, or hot water systems

- Cool systems before maintenance

Applications: Boilers, chillers, heat exchangers

MEP Isolation (Building Systems)

MEP isolation focuses on Mechanical, Electrical, and Plumbing systems in buildings and infrastructure projects.

Common Isolation Points:

- Electrical DBs and MCC panels

- HVAC systems (AHUs, FCUs, chillers)

- Pumps, motors, and valves

- Hot and chilled water lines

MEP Hazards if Not Properly Isolated:

- Electric shock

- Sudden fan or pump startup

- Hot/chilled water release

- Flooding or system damage

Plant Isolation (Industrial & Process Safety)

Plant isolation involves complex, high-energy systems often requiring permit-to-work and isolation certificates.

Plant Isolation Includes:

- Energy isolation (LOTO)

- Process line and vessel isolation

- Coordination between departments

Plant Hazards:

- High-pressure release

- Steam burns

- Toxic gas exposure

- Fire or explosion

- Multiple energy source interaction

Common Hazards Across Isolation Types

- Unexpected equipment startup

- Release of stored electrical, mechanical, hydraulic, or pneumatic energy

- Chemical or gas leakage

- Thermal burns or frost injuries

- Crushing or entanglement

⚠️ Most fatalities occur during maintenance, not normal operation.

Control Measures for Isolation Hazards

- Written isolation procedures for MEP and plant systems

- Identification of all energy sources

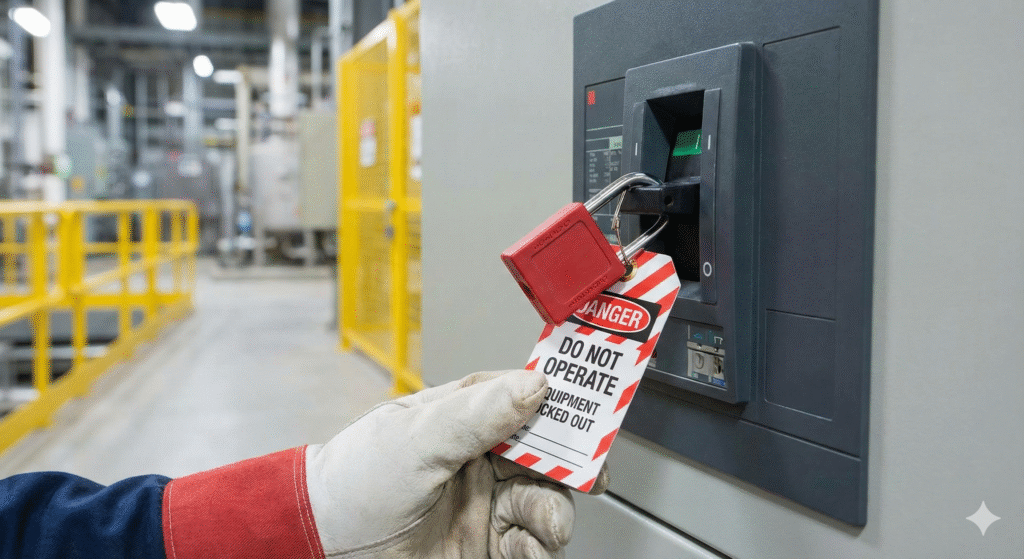

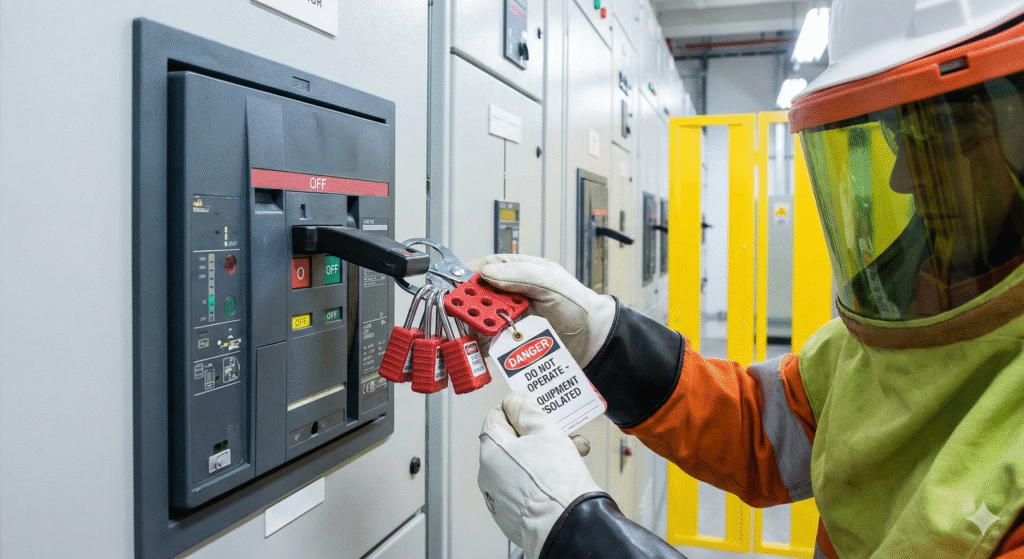

- Lockout–Tagout (LOTO) and physical isolation

- Permit-to-work and isolation certificates

- Trained and authorized personnel only

- Verification via testing

- Clear signage and communication

- Supervisor and safety officer oversight

Step-by-Step Isolation Process

- Preparation: Identify system, energy sources, isolation points, and drawings

- Shutdown: Stop system using normal controls

- Isolation: Physically disconnect or block energy sources

- Lockout/Tagout: Apply locks and danger tags

- Release Stored Energy: Drain, depressurize, or cool as needed

- Verification: Test and confirm zero-energy state

- Work Execution: Perform maintenance safely

- De-isolation: Restore systems safely after work

International Safety Standards Supporting Isolation

- OSHA: Hazardous Energy Control (LOTO) standards

- HSE UK: Safe isolation for MEP and industrial systems

- ILO: Worker protection and energy control guidelines

Isolation is not just a procedure — it is a life-saving discipline critical for MEP systems, industrial plants, and high-energy operations.