How Incomplete Maintenance Creates Hazards and Why Safety Observations Focus on Maintenance

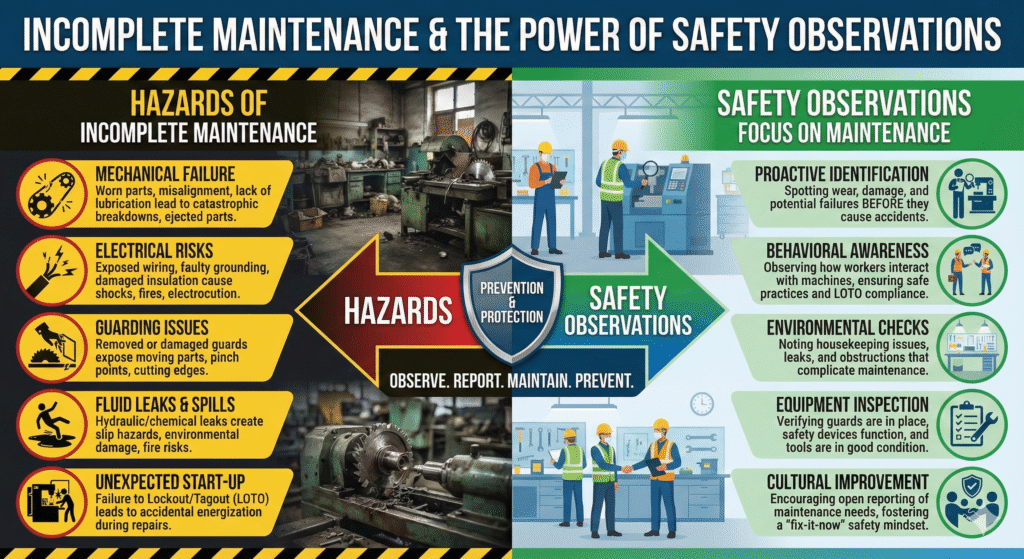

Maintenance is meant to remove danger, but in many workplaces, hazards are created because maintenance is incomplete, rushed, or poorly controlled. This is the primary reason why safety departments raise a large number of safety observations against maintenance-related activities.

This issue is not about blaming maintenance teams. It is about understanding a critical reality:

How maintenance is performed matters more than whether maintenance is performed.

The Real Issue: Half-Done and Neglected Maintenance

Maintenance becomes a safety hazard when work is left incomplete or poorly closed out. Common unsafe conditions include:

- Jobs left unfinished

- Temporary repairs treated as permanent solutions

- Machine guards removed and not reinstalled

- Electrical panels left open or unsecured

- Oil and fluid leaks ignored

- Poor housekeeping after maintenance

- No final safety or functionality check

A machine in this condition is often more dangerous than a machine that is completely shut down.

Why Safety Observations Mostly Target Maintenance

Safety teams focus heavily on maintenance because:

- Maintenance alters the normal safe condition of machines

- Safety devices are frequently removed during repair work

- Partial isolation increases energy-related risks

- Maintenance defects are visible, immediate, and high-risk

- Accident investigations repeatedly link maintenance failures to serious injuries

Safety observations are raised to prevent harm before it occurs, not to find faults.

Importance of Proper Maintenance of Machines

Proper maintenance ensures:

- Safe operation of equipment

- Protection of operators and technicians

- Compliance with legal and regulatory requirements

- Reduced breakdowns and downtime

- Extended equipment life

Maintenance is not complete until the machine is safe, guarded, tested, and clean.

Types of Maintenance and Their Safety Impact

Choosing the correct maintenance strategy directly affects workplace safety.

Preventive Maintenance (Planned Preventive Maintenance – PPM)

What it is:

Maintenance carried out at scheduled intervals.

Examples:

- Lubrication schedules

- Guard and interlock inspections

- Replacement of worn components

- Electrical tightening and panel cleaning

Safety Value:

- Reduces emergency repairs

- Prevents sudden failures

- Allows proper isolation and planning

- Minimizes rushed, unsafe work

Risk if ignored:

Unexpected failures force high-risk breakdown maintenance.

Condition-Based Maintenance

What it is:

Maintenance based on equipment condition rather than fixed time.

Methods include:

- Vibration monitoring

- Temperature checks

- Oil analysis

- Visual defect reporting

Safety Value:

- Early detection of faults

- Reduced pressure on technicians

- Better control of critical assets

- Less emergency intervention

Risk if ignored:

Hidden defects escalate into dangerous failures.

Predictive Maintenance

What it is:

Advanced use of data trends to predict failures before they occur.

Safety Value:

- Highest level of risk control

- Eliminates panic maintenance

- Allows safe scheduling

- Reduces human error

Risk if ignored:

Organizations remain reactive instead of proactive.

Breakdown Maintenance

What it is:

Maintenance performed after equipment failure.

Safety Impact:

- High stress and time pressure

- Increased shortcuts

- Poor isolation practices

- Elevated accident risk

Key Reality:

Most serious maintenance-related accidents occur during breakdown repairs.

Workplace Maintenance Is Equally Important

Poor workplace maintenance leads to:

- Slips, trips, and falls

- Blocked emergency exits

- Unsafe access to equipment

- Inadequate lighting and ventilation

- Fire hazards due to clutter

A well-maintained workplace supports safe maintenance and safe operations.

How Poor Maintenance Creates Ongoing Hazards

Negligence often develops from:

- “We will fix it later” mindset

- Weak supervision

- No maintenance closure system

- Poor shift handovers

- Inadequate training

Over time, these small failures become normalized risks.

Role of the Safety Department in Maintenance

Safety teams raise observations because:

- They recognize patterns before accidents occur

- They ensure legal and regulatory compliance

- They protect workers from hidden hazards

- They verify machines are safe before use

Safety involvement is support, not interference.

How Maintenance Can Reduce Safety Observations

Practical actions that work:

- Fully complete every maintenance task

- Reinstall all guards and covers

- Conduct final safety and function checks

- Clean the area before handover

- Use maintenance completion checklists

- Involve safety in high-risk maintenance

- Follow lockout/tagout procedures strictly

Good maintenance naturally results in fewer safety findings.

The Shared Responsibility

Maintenance removes faults.

Safety removes risks.

When maintenance is careless, safety must intervene.

When maintenance is professional, safety becomes a partner.

Conclusion

Maintenance of machines and workplaces is one of the strongest safety controls in any organization. Preventive, condition-based, and predictive maintenance reduce hazards, while breakdown maintenance significantly increases risk.

Incomplete maintenance does not just fail to fix problems, it creates new ones.