Types of Scaffold, Components, Inspection, Hazards, Incidents:

1. Introduction.

Scaffold is a temporary structure used in construction to support workers, tools, and materials at height. It is one of the most common access systems on construction sites, but it is also one of the leading causes of serious injuries and fatalities when not properly designed, erected, or inspected. According to guidance from Occupational Safety and Health Administration, Health and Safety Executive, and the International Labour Organization, most scaffold accidents are preventable through proper planning, competent supervision, and regular inspections.

2. Types of Scaffolds Commonly Used on Construction Sites

a. Supported Scaffold

- The most commonly used scaffold in construction

- Supported by frames, poles, or legs resting on the ground

- Widely used for masonry, plastering, and general construction work

b. Suspended Scaffold

- Platform suspended by ropes or steel cables from an overhead structure

- Commonly used for façade work, painting, and high-rise maintenance

- Requires strict fall protection and anchorage systems

c. Mobile (Rolling) Scaffold

- Supported scaffold mounted on wheels or casters

- Used for indoor and short-duration tasks

- Must be locked during use and moved only when unoccupied

d. Cantilever / Needle Beam Scaffold

- Supported by needles or beams projecting from the structure

- Used where ground access is not possible (roads, entrances, waterways)

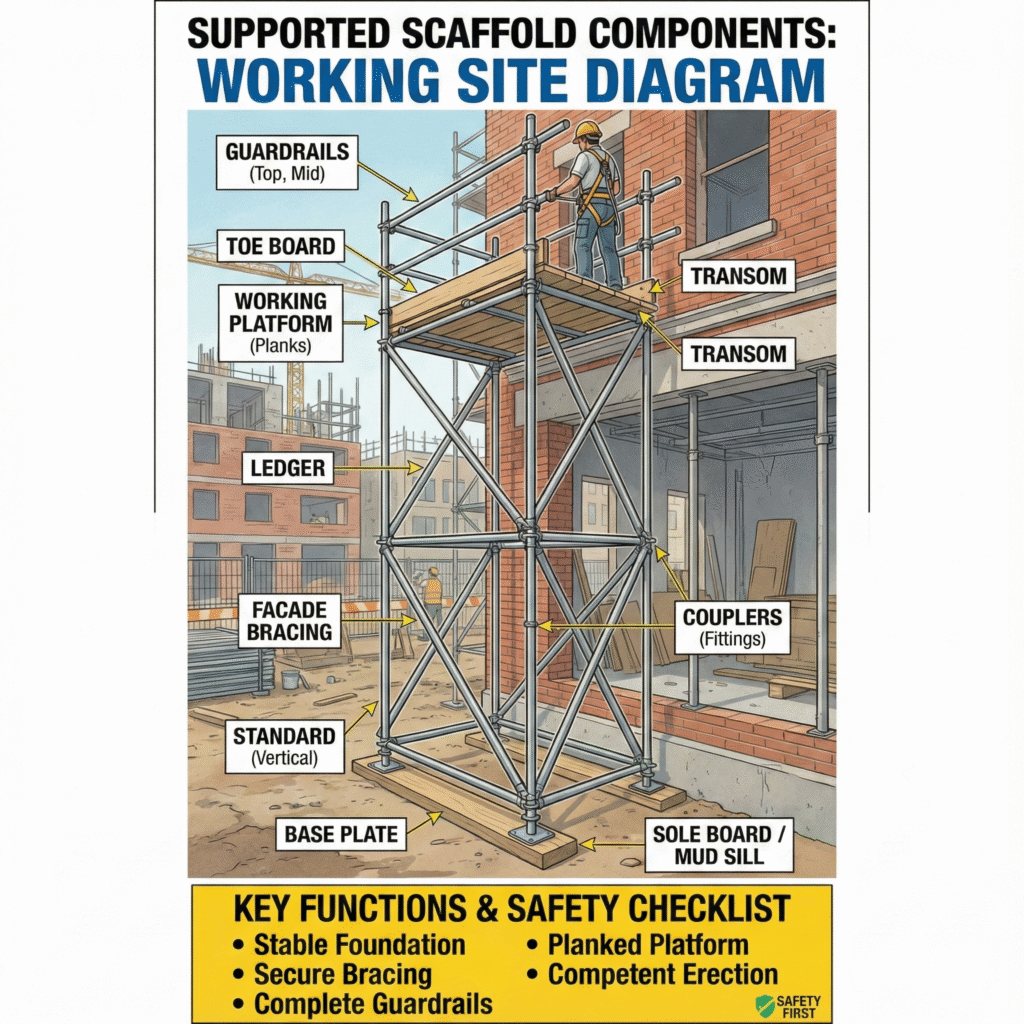

3. Main Components of a Scaffold

A safe scaffold system consists of the following essential parts:

- Base Plates & Sole Boards – Distribute the load safely to the ground

- Standards (Uprights) – Vertical members transferring load to the base

- Ledgers – Horizontal tubes connecting standards

- Transoms – Support scaffold boards and platforms

- Bracing – Provides lateral and longitudinal stability

- Working Platforms / Planks – The surface where workers stand

- Guardrails & Midrails – Prevent falls from height

- Toeboards – Prevent tools and materials from falling

- Access Ladders / Stair Towers – Safe means of access and egress

4. How to Inspect a Scaffold (Step-by-Step)

Scaffold inspection must be conducted by a competent person, as required by OSHA, HSE UK, and ILO guidance.

Step 1: Foundation Check

- Ensure firm, level ground

- Base plates and sole boards properly installed

Step 2: Structural Integrity

- Check standards, ledgers, transoms, and braces for damage or corrosion

- Confirm correct spacing and secure connections

Step 3: Platform Safety

- Platforms fully planked with no large gaps

- Planks free from cracks, splits, or excessive deflection

Step 4: Fall Protection

- Guardrails, midrails, and toeboards installed where required

- Fall arrest systems in place for suspended scaffolds

Step 5: Access and Housekeeping

- Safe access provided (ladders or stairs)

- No debris, loose materials, or slippery substances

Step 6: Environmental Conditions

- Assess wind, rain, heat, or night-time visibility

- Stop work if conditions make scaffold use unsafe

Inspections should be carried out before first use, daily before work starts, after any modification, and after adverse weather.

5. Scaffold Tagging System

Scaffold tags provide a visual safety status at access points:

- Green Tag – Scaffold inspected and safe for use

- Yellow Tag – Caution: limited use or under modification

- Red Tag – Unsafe scaffold – DO NOT USE

Tagging systems are strongly recommended by HSE UK and widely adopted as best practice worldwide.

6. Common Scaffold Hazards

Scaffold work exposes workers to multiple hazards, including:

- Falls from height due to missing guardrails or unsafe access

- Scaffold collapse from overloading or weak foundations

- Falling objects striking workers below

- Electrocution from proximity to overhead power lines

- Slips and trips caused by poor housekeeping

- Weather-related risks such as strong winds, rain, or extreme heat

7. Previous Scaffold-Related Incidents and Losses

- Willow Island Scaffold Collapse (USA) – One of the deadliest scaffold disasters, killing 51 workers due to structural failure and poor construction sequencing.

- Repeated OSHA-recorded incidents show fatalities caused by workers falling from unguarded platforms or scaffold collapses due to overloading.

- HSE UK reports highlight frequent injuries from unsafe access and lack of inspection.

- ILO global data indicates scaffold accidents contribute significantly to construction fatalities, particularly in developing countries, leading to loss of life, project delays, legal penalties, and reputational damage.

These incidents demonstrate that ignoring scaffold safety results in human loss, financial loss, and legal consequences.

8. Standards and References

This article aligns with guidance from:

- Occupational Safety and Health Administration – 29 CFR 1926 Subpart L (Scaffolds)

- Health and Safety Executive – Work at Height Regulations and scaffold inspection guidance

- International Labour Organization – Safety and Health in Construction Convention (C167)